Optiger Telecentric Lenses: The Precision Tool for Metrology

2025-12-23

As the application scope of machine vision expands, user needs have become increasingly diverse, with one common demand being high requirements for imaging quality. However, traditional lenses are struggling to meet these needs.

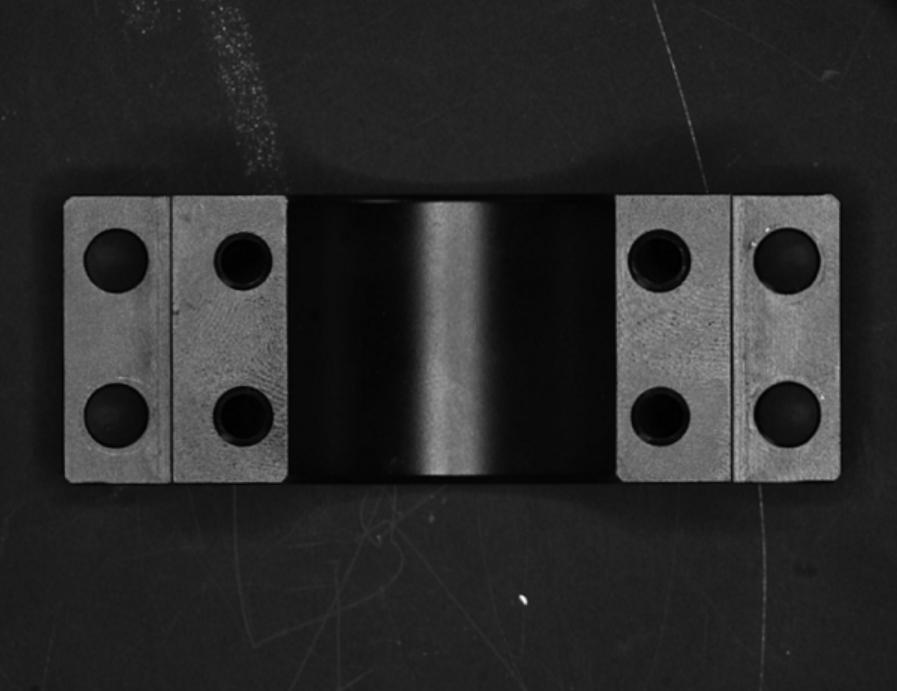

In the field of dimension measurement, for example, ordinary lenses exhibit perspective distortion (the "near-large, far-small" effect) when imaging objects with height differences. This means that different software calibrations are required for different working distances to obtain accurate dimensions. As shown in Figure 1, the measured dimensions of the top and bottom of the fixture deviate significantly from the actual values. Additionally, issues such as poor lens uniformity and high distortion rates affect measurement accuracy and efficiency.

Figure 1: Ordinary lens measuring an object with height differences

To address these challenges, the optimal solution is to use telecentric (double telecentric) lenses for inspection. Their unique advantage lies in suppressing perspective distortion, and the key metric for this capability is telecentricity—smaller telecentricity indicates stronger distortion suppression. OPTIGER's double telecentric lenses achieve a telecentricity of less than 0.05° across the entire field of view (FOV) and full depth of field (DOF). Combined with sophisticated optical design, the distortion rate is also less than 0.05% across the entire FOV and DOF, enabling direct dimension reading from images of objects within the DOF. This significantly improves inspection efficiency and accuracy.

Figure 2: OPTIGER Bi-telecentric lens measuring an object with height differences

Figure 2: OPTIGER Bi-telecentric lens measuring an object with height differences In the field of small FOV inspection, many lenses on the market either fail to meet magnification requirements, produce dark images, have excessively short working distances, or suffer from severe distortion. Targeting small FOV inspection, OPTIGER has designed and produced a series of object-side telecentric lenses. The most representative model is the high-magnification coaxial object-side telecentric lens OTL11.5-100-110CT. Boasting 10x high magnification, it delivers exceptional performance with an object-side resolution of 3.221 μm, DOF of 0.02 mm, and a working distance of 110 mm. When paired with a 2/3” sensor camera, it offers a maximum FOV of only 1.15 mm.

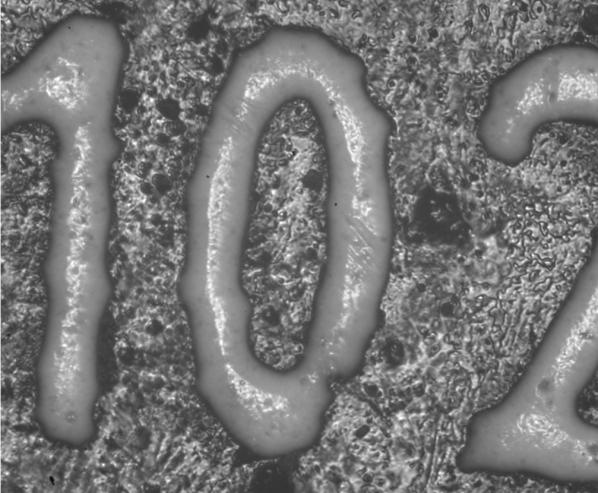

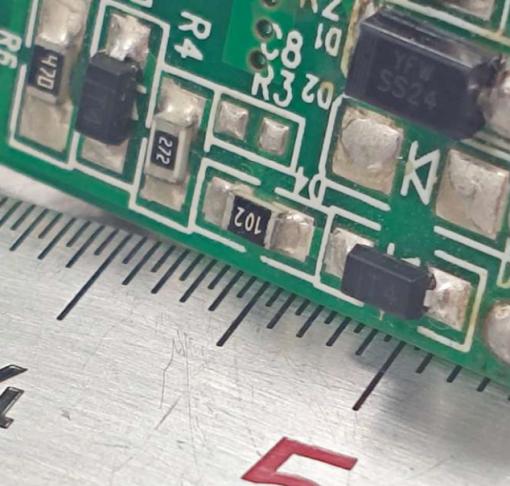

Figure 3 demonstrates the OTL11.5-100-110CT inspecting numeric markings on a chip resistor, where the height of the small characters is approximately 0.6 mm. While these characters appear smooth and flat to the naked eye, the 10x magnification reveals surface irregularities and edge burrs. The imaging effect is excellent, with visually uniform brightness and sharp edges.

Figure 3: OPTIGER 10x object-side telecentric lens inspecting numeric markings on a chip resistor

Figure 3: OPTIGER 10x object-side telecentric lens inspecting numeric markings on a chip resistor

Figure 4: Small characters on a chip resistor (size < 1 mm)

High-magnification lenses typically face challenges with lighting, resulting in dark images. To solve this, OPTIGER integrated a coaxial design. By inserting a point light source, light is emitted from the lens via a beam splitter prism, illuminates the object surface, and then returns to the lens for imaging. This achieves front illumination with over 90% uniformity, easily illuminating the object surface. The coaxial light emitted by the telecentric lens has higher collimation and greater sensitivity to the object's surface shape, simplifying surface defect inspection. Through robust optical design and strict manufacturing standards, OPTIGER ensures that the coaxial design does not compromise imaging quality—maintaining consistent brightness and resolution across the FOV center and edges. This greatly enhances the flexibility and simplicity of supporting mechanical structure design. For inspecting the surfaces and micro-defects of tiny objects, the OTL11.5-100-110CT lens is an ideal choice, thanks to its outstanding contrast, resolution, and convenient coaxial design.

Figure 5: OTL11.5-100-110CT

Beyond this distinctive model, the series offers a wide range of options: magnifications from 0.5x to 10x, working distances from 65 mm to 300 mm, and coaxial design availability for select models. Whether for compact testing spaces or applications requiring long working distances, these lenses provide a solution. Through rigorous optical design, all object-side telecentric lenses in the series achieve a distortion rate of less than 0.05% and telecentricity of less than 0.05° across the entire FOV and DOF, delivering high-precision, accurate imaging for users.

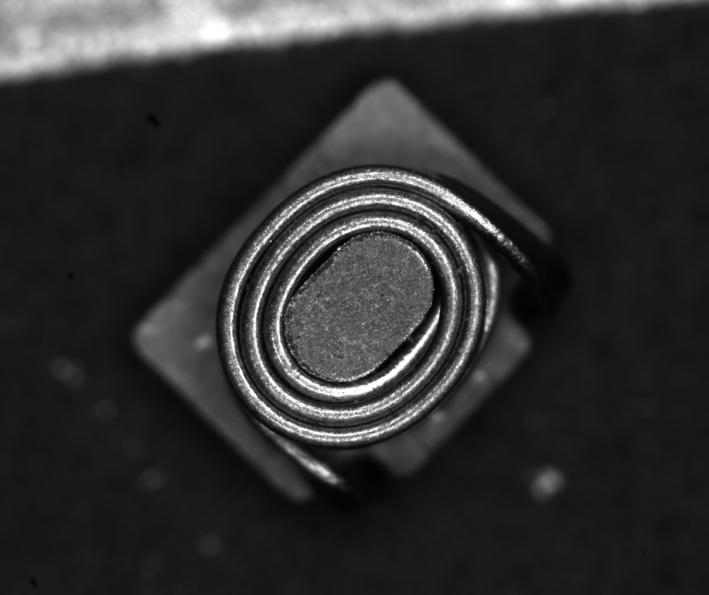

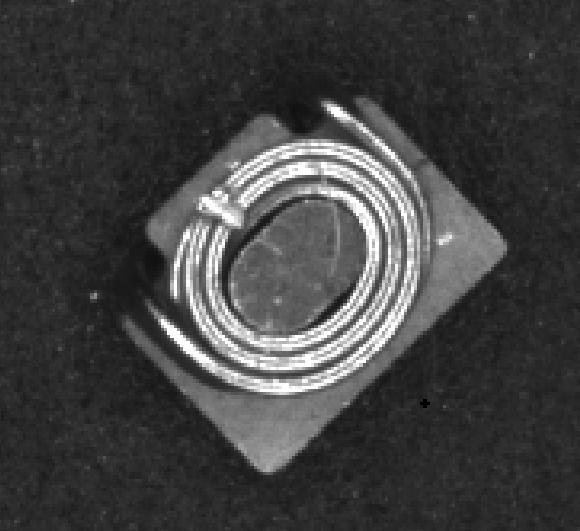

In the field of large FOV double telecentric lenses, OPTIGER maintains its commitment to excellence. The following demonstrates OPTIGER lenses inspecting small inductors—less than 2 mm in length, with wound magnetic coils narrower than 0.15 mm. Figure 6 shows inspection using the OPTIGER OTL11.5-20-110CT 2x coaxial object-side telecentric lens. With a 5.7 mm FOV, the lens easily handles the inspection, even resolving surface machining textures clearly.

Figure 6: OPTIGER lens inspecting a small inductor

Figure 6: OPTIGER lens inspecting a small inductor

Figure 7: OPTIGER 2x lens inspecting a small inductor (magnified view)

Figure 8 showcases the TTL18.5-105-160C lens performing batch inspection of small inductors. Featuring a relatively large 105 mm FOV, this lens offers an object-side resolution of 26.69 μm, DOF of 18.08 mm, and a magnification of 0.176. As seen in Figure 9, even though the objects occupy less than 1/50 of the actual FOV, the TTL18.5-105-160C still delivers clear imaging—each coil is distinguishable, and surface scratches are clearly visible. Consistent imaging quality across the entire FOV significantly boosts inspection efficiency.

Figure 8: OPTIGER double telecentric lens batch-inspecting small inductors

Figure 8: OPTIGER double telecentric lens batch-inspecting small inductors

Figure 9: Magnified view of small inductors inspected by OPTIGER Bi-telecentric lens

Figure 10: TTL18.5-105-160C

Notably, a 105 mm FOV is considered medium-sized in OPTIGER's product lineup. The double telecentric series covers FOV ranges from 11.5 mm to 315 mm and supports sensor sizes from 1/3” to full-frame. Every model achieves a measured distortion rate of less than 0.05% and telecentricity of less than 0.05° across the entire FOV and DOF. Beyond optical design, OPTIGER pays meticulous attention to details: lenses adopt anodized blackening, anti-reflective paint coating, and built-in anti-glare threads to minimize stray light, ensuring uniformity and inspection repeatability. Customizable apertures are also available to balance resolution and DOF as needed. OPTIGER telecentric lenses—your optical tool of choice for precision inspection. With OPTIGER, easily enhance inspection efficiency and tackle diverse imaging challenges.

Figure 11: Group photo of selected OPTIGER products